Resources

News, case studies, and insights from General Lattice.

Taking Shape: A conversation with Carol Kijac on the impact of additive manufacturing in supply chain and logistics

Exploring the impact of digital technologies on supply chain performance, innovative uses of Additive Manufacturing across industries, and the strategic implications of reshoring.

General Lattice Raises $1 Million in Pre-Seed Funding Led by AP Ventures

General Lattice announced it has raised $1 million in pre-seed funding led by AP Ventures LLC, the strategic investment arm of All Points Logistics LLC.

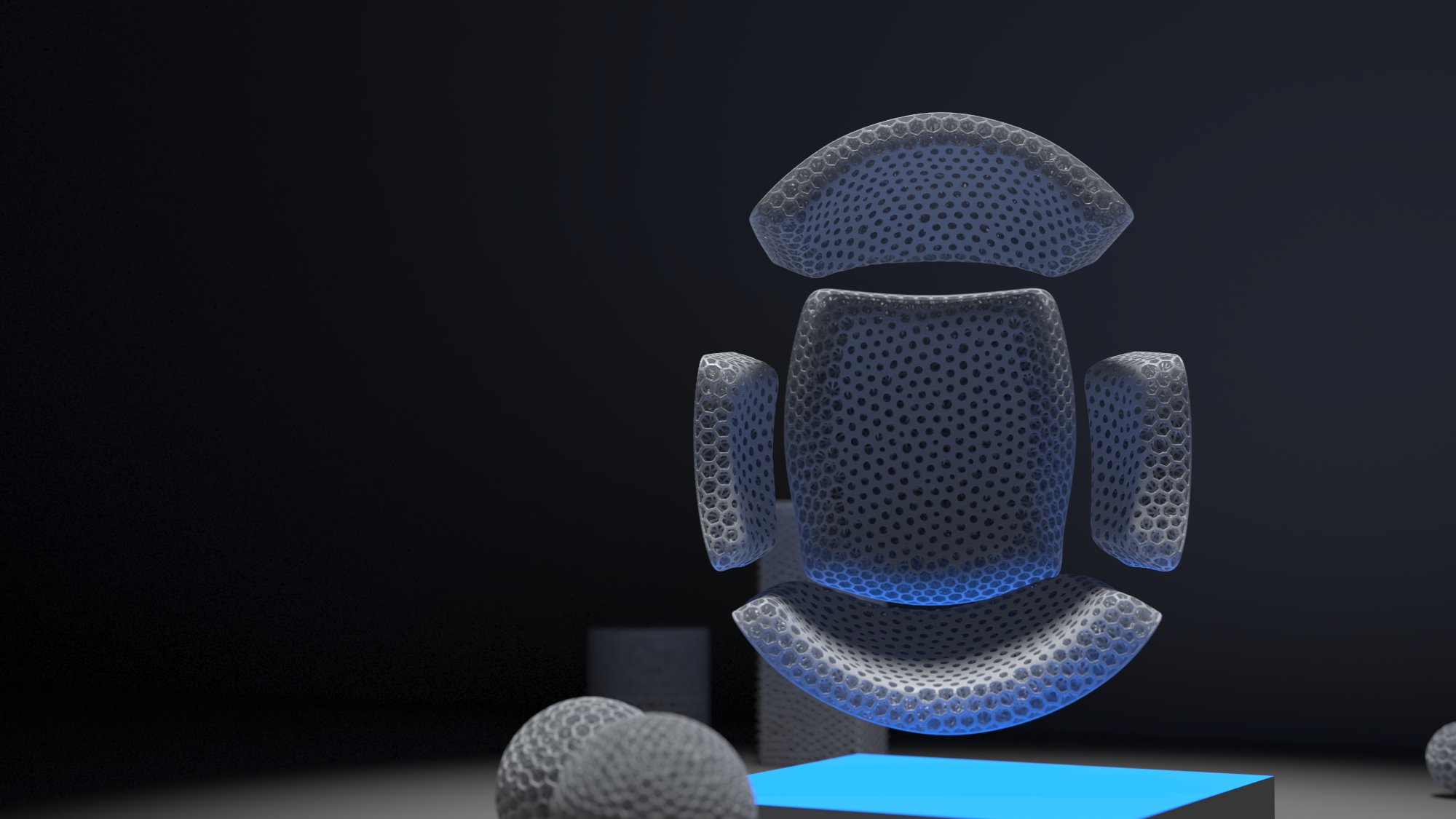

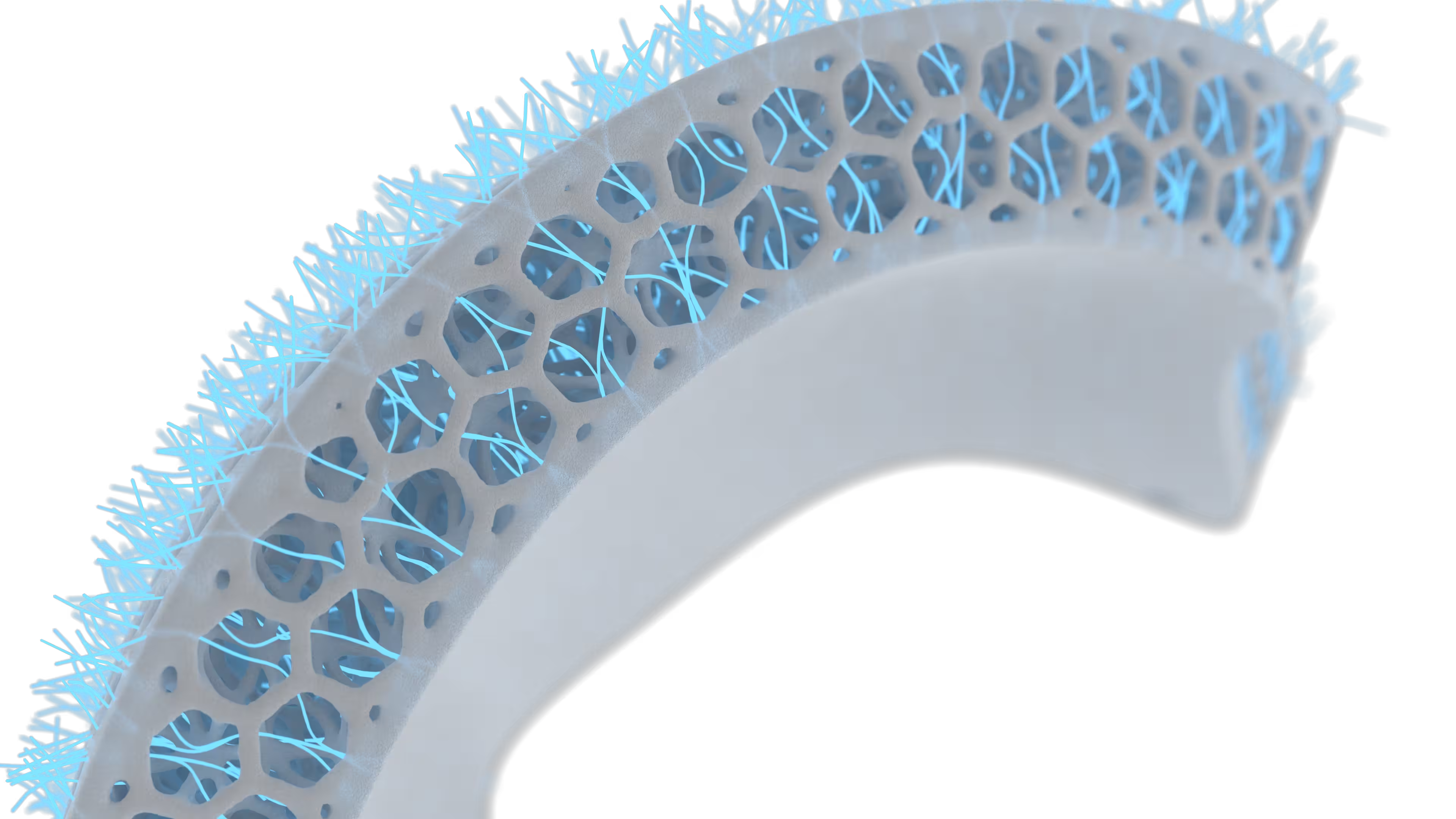

General Lattice Secures Contract with the U.S. Army to Improve Energy Absorption of Next Generation Combat Helmet with 3D Printing

General Lattice is developing a predictive modeling toolset to design and generate lattice materials based on real-world data, improving impact absorption technology.

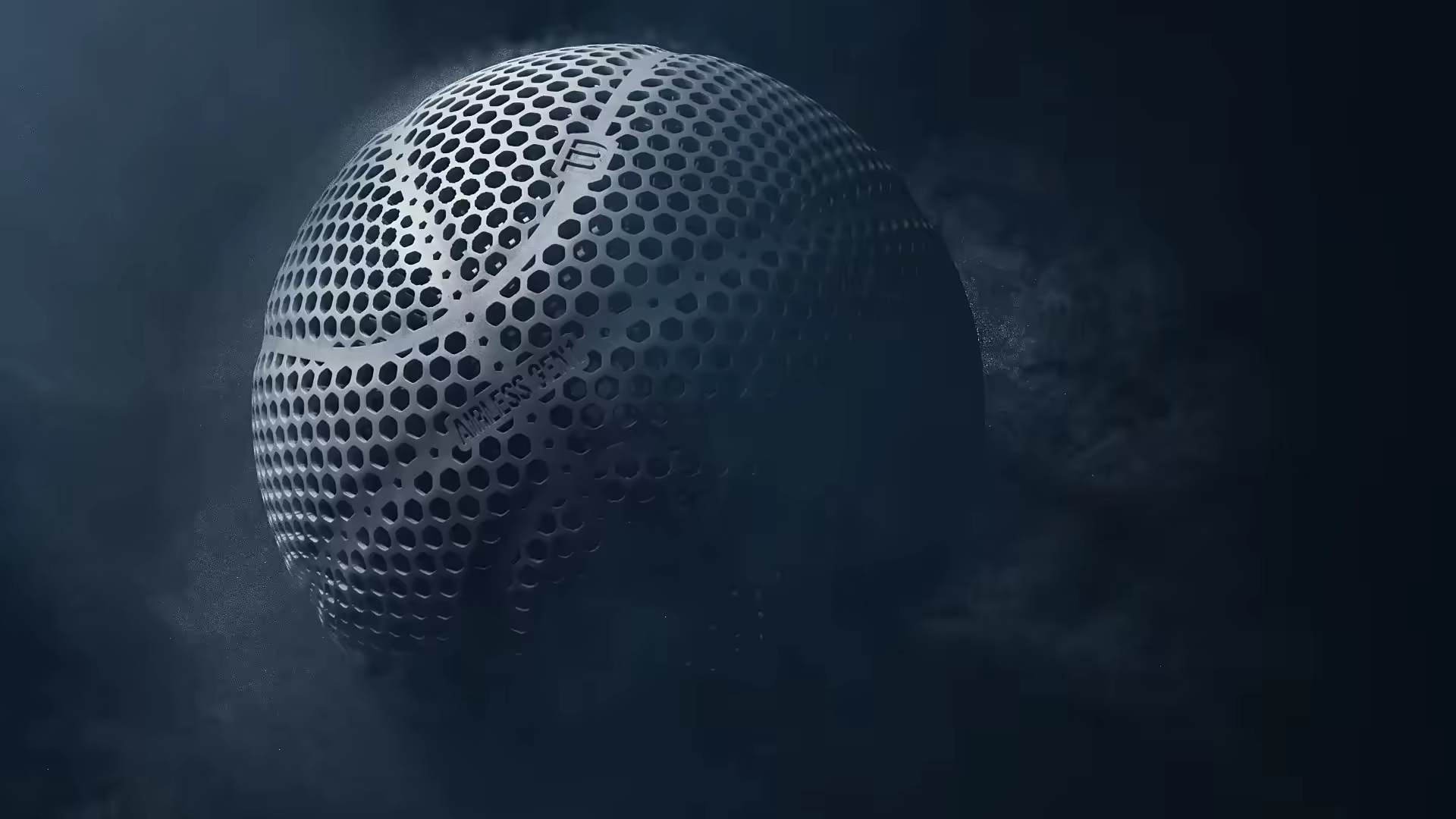

Wilson Airless Basketball

A 3D printed airless basketball that matched performance specs. Solved in 3 months—a challenge Wilson had been working on for 4 years.

Automated Design-to-Manufacturing Pipeline

Over 900 unique manufacturing files generated in less than 1 second—a process that originally took approximately 3 months.

Configurable Payload Systems

Multiple flight-ready units demonstrated at an Army xTech event—2 weeks from concept to flight.

Automated CAD-to-Simulation Workflow

File preparation reduced from 10 hours to under 1 second, accelerating the design optimization cycle by orders of magnitude.